We manage waste from the production processes of automotive, graphic and industrial industries in various segments, as well as financial institutions.

We provide equipment and employees onsite to optimize the process and correctly allocate waste.

Collection is performed on a scheduled basis, with operational equipment for loading and unloading, using the most appropriate equipment to accommodate each type of material. In order to optimize collection, we have compactor containers that reduce the number of trips.

We perform a manual selection process in which we separate each type of material in a space, removing impurities and other waste that may be reused. Following this step, the material goes to the conveyor belt, which will take it to the crusher, if necessary, and then to the compactor.

Our crusher has a capacity of 15 metric tons per hour. It performs a stealthy and rapid fragmentation of materials. For even more secretive cases, such as financial institutions, we provide shredders of smaller capacity that cut the paper in the form of trims. The entire process can be supervised and inspected by our customers.

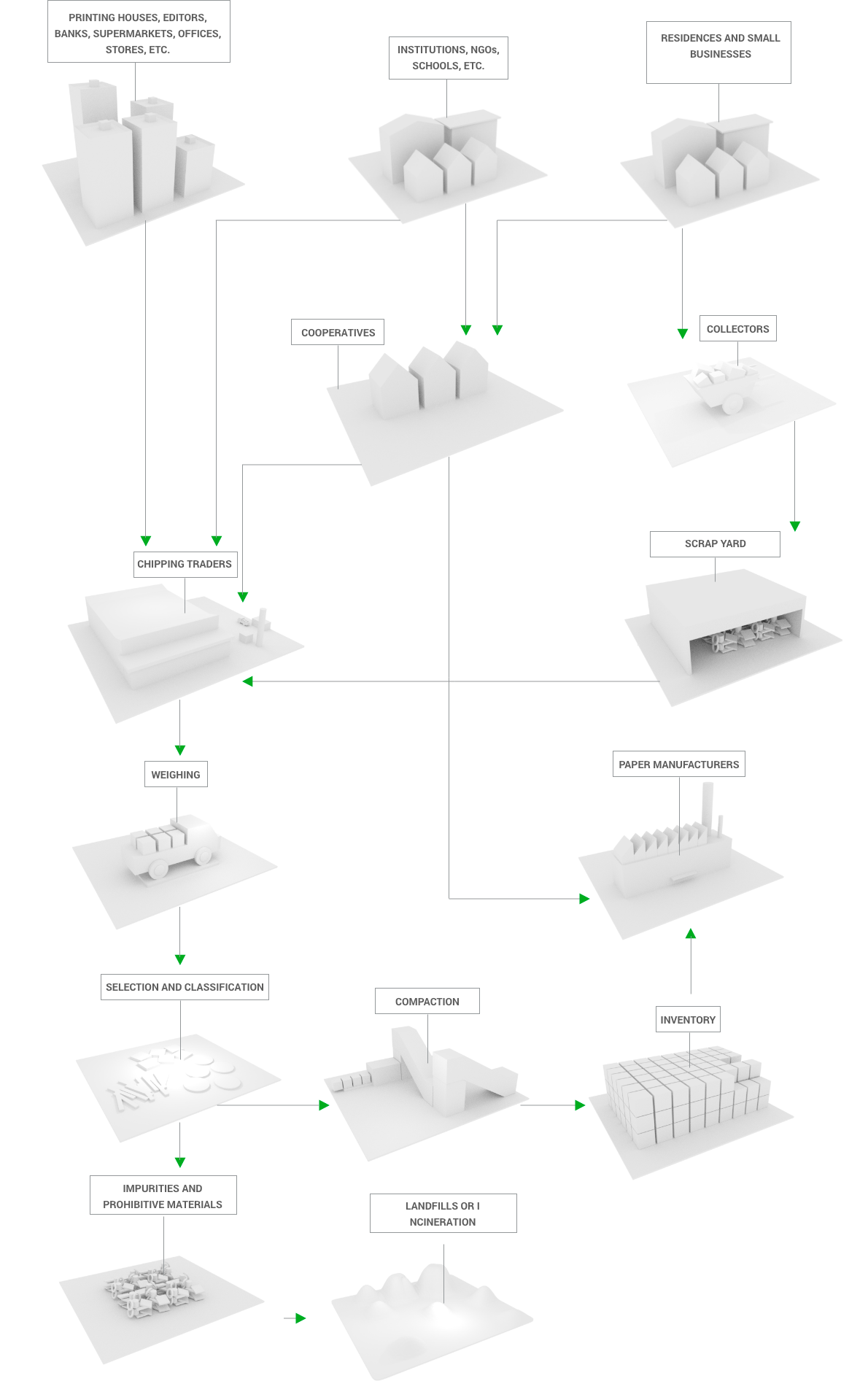

Chipping marketing process

The materials coming from Industrias, Institutions, NGOs, Cooperatives and Scrap Metals arrive at Aparista, are heavy and go through the classification process. The waste is destined for the landfill and the others are compacted, stocked and then sold to paper mills.